1. Small-Scale 3D Printing for Research & Prototyping

At the Centre of Excellence for Advanced 3D Concrete Printing, we utilize a range of 3D printing technologies to support research, prototyping, and innovation in construction automation. One of our key tools for rapid prototyping is the Creality Ender 3 (PLA Filament 3D Printer).

Specifications & Features:

- Printing Technology: Fused Deposition Modeling (FDM)

- Build Volume: 220 x 220 x 250 mm

- Materials Supported: PLA, TPU, and ABS (with modifications)

- Precision: Layer resolution of 0.1 – 0.4 mm

- Applications: Small-scale models, testing enclosures for electronic sensors, and proof-of-concept designs

Applications in 3D Concrete Printing Research

The Ender 3 plays a vital role in our research and development process. Before scaling up to full-scale concrete structures, we:

- Prototype design iterations in PLA before concrete printing

- Validate sensor placements in Smart Safety Helmet research

- Develop scaled-down versions of 3D concrete-printed structures

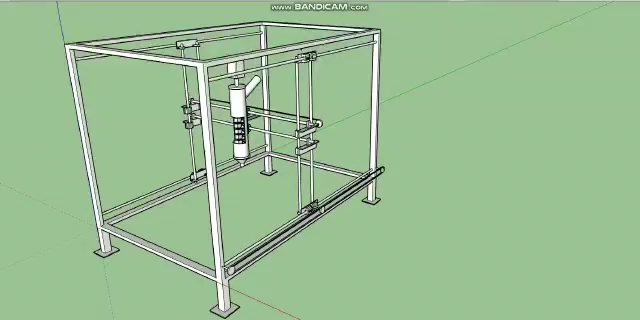

2. Small-Scale 3D Concrete Printer (1.5m x 1m x 1m) – Centre of Excellence for Advanced 3D Concrete Printing

The 1.5m x 1m x 1m Small-Scale 3D Concrete Printer at the Centre of Excellence for Advanced 3D Concrete Printing, PCCoE, Pune, is a precision-driven gantry-based system designed for research, prototyping, and small-scale structural experimentation.

Key Features & Specifications:

- Printing Volume: 1.5m (L) × 1m (W) × 1m (H)

- Printing Mechanism: Gantry-based extrusion system

- Material Compatibility: Specially formulated cementitious and geopolymer-based concrete mixes

- Nozzle System: Adjustable nozzle for controlled layer deposition

- Layer Thickness: 5mm – 20mm (adjustable)

- Extrusion Speed: Variable, optimized for different mix viscosities

- Control System: CNC/robotic system with G-code-based automation

- Power Requirements: Standard 220V AC, 50Hz

Applications in Research & Development:

Prototype Testing – Scaled-down models before full-scale concrete printing

Material Experimentation – Testing sustainable and alternative cementitious materials

Component Fabrication – Printing architectural elements, facades, and experimental structures

Sensor & Automation Integration – Developing Smart Safety Helmet enclosures and embedded IoT applications

This printer serves as a bridge between desktop 3D printing (PLA-based) and full-scale concrete printing, allowing for optimized designs and cost-effective material testing before executing large-scale projects.

3. Large-Scale 3D Concrete Printer (5m x 5m x 5m) – Centre of Excellence for Advanced 3D Concrete Printing

The 5m x 5m x 5m Large-Scale 3D Concrete Printer at the Centre of Excellence for Advanced 3D Concrete Printing, PCCoE, Pune, is a state-of-the-art gantry-based additive manufacturing system designed for printing full-scale civil engineering structures with precision and efficiency.

Key Features & Specifications:

- Printing Volume: 5m (L) × 5m (W) × 5m (H)

- Printing Mechanism: Gantry-based robotic extrusion system

- Material Compatibility: High-performance cementitious and geopolymer concrete mixes

- Nozzle System: Custom-designed extruder with automated flow control

- Layer Thickness: 10mm – 50mm (adjustable based on structure and mix design)

- Extrusion Speed: Variable, optimized for different concrete rheologies

- Control System: CNC-controlled automation with real-time monitoring

- Power Requirements: Three-phase 440V AC

Applications in Construction & Research:

- Full-Scale Structural Printing – Walls, beams, columns, and architectural components

- Sustainable Housing Solutions – Development of cost-effective affordable homes

- Automation in Construction – Reducing manual labor and enhancing precision

- Integration with Smart Technologies – Embedding sensors, IoT, and smart safety features

- Material & Structural Testing – Optimizing concrete mix designs for durability and sustainability

This printer plays a crucial role in the "Development of 3D Concrete Printed Full-Scale Civil Engineering Structures Using Gantry Frame Mechanism" research initiative at the Centre of Excellence.